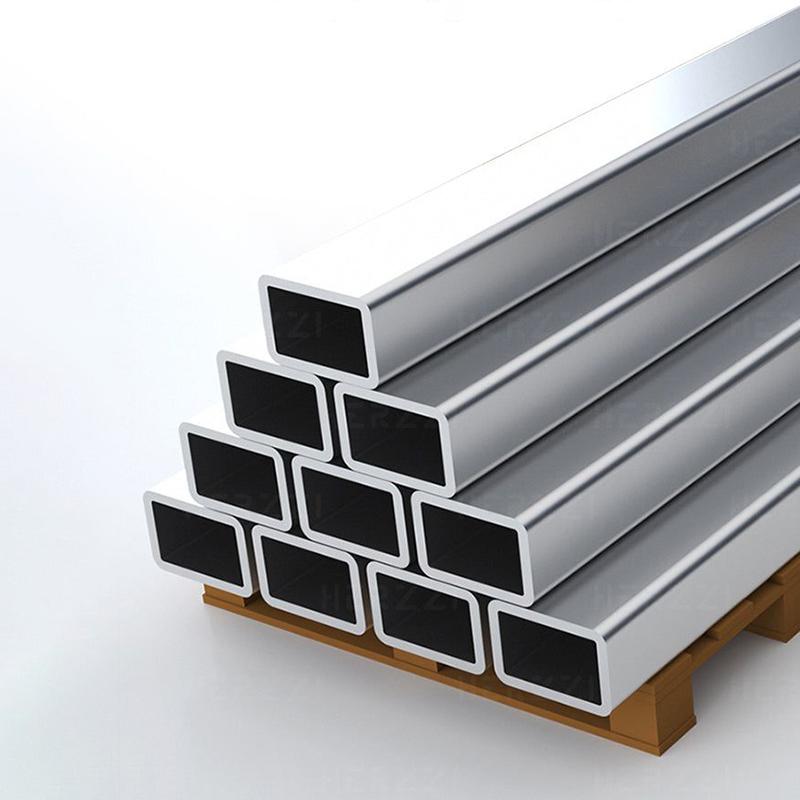

How Shower Enclosure Aluminum Profiles Stay Rust-Free in Wet Environments

Shower enclosure aluminum profiles resist rust because aluminum forms a natural protective layer. Rigorous fog and moisture resistance tests confirm their durability in wet bathrooms. Advanced surface treatments increase corrosion resistance by up to 100 times compared to untreated surfaces. With minimal care, these profiles keep their appearance and strength for years.

Key Takeaways

- Aluminum forms a natural oxide layer that protects it from rust and corrosion, making it ideal for wet bathroom environments.

- Surface treatments like anodizing and powder coating greatly increase aluminum's resistance to moisture and chemicals, extending its lifespan.

- Simple maintenance, such as gentle cleaning and drying after use, helps keep aluminum shower profiles strong and looking new for years.

Why Shower Enclosure Aluminum Profiles Resist Corrosion

Natural Protective Layer of Aluminum

Aluminum protects itself by forming a thin, invisible oxide layer when it meets air. This layer acts like a shield, stopping water and air from reaching the metal underneath. In bathrooms, where moisture is everywhere, this natural barrier keeps the metal safe. Scientific tests show that even after weeks in salty water, aluminum with a special oxide coating stays strong and dry. Researchers found that adding tiny particles, like TiO₂ and special chemicals, makes this layer even tougher. The result is a surface that water cannot easily touch, which helps shower enclosure aluminum profiles last longer in wet spaces.

Difference Between Rust and Corrosion

Steel and aluminum react differently to water and air. Steel rusts because iron in the metal turns into iron oxide, which flakes away and weakens the structure. Moisture speeds up this process. Some metals, like stainless steel, form a thin layer of chromium oxide that protects them, but this layer can break down in salty or acidic places. Aluminum, on the other hand, quickly forms a stable oxide layer that does not flake off. This layer stays in place and keeps protecting the metal. Humidity changes how thick this layer gets, but it always helps slow down corrosion. That is why shower enclosure aluminum does not rust like steel, even in steamy bathrooms.

Tip: Aluminum’s oxide layer repairs itself if scratched, so the protection never stops.

Aluminum Alloys Used in Shower Enclosures

Manufacturers choose special aluminum alloys for shower enclosure frames. The most common types are 6063 and 6463. These alloys offer a strong mix of hardness and flexibility, making them perfect for holding glass panels. They also resist bending and cracking. After shaping, each piece goes through strict quality checks. Tests measure how much force the frame can handle and how well it stands up to water and chemicals. Anodizing, a process that thickens the oxide layer, adds even more protection. Industry standards, like AMS 2472, require tests for coating thickness, strength, and resistance to salt spray. These steps make sure shower enclosure aluminum profiles stay safe and look good, even after years of use in damp bathrooms.

Surface Treatments and Maintenance for Shower Enclosure Aluminum

Anodizing and Its Benefits

Anodizing creates a strong, protective layer on aluminum. This process thickens the natural oxide layer, making the surface harder and more resistant to corrosion. Many technical studies confirm the effectiveness of anodizing. The table below shows how different surface treatments perform in corrosion resistance tests:

| Surface Treatment Type | Test Methodology | Key Findings on Corrosion Resistance |

|---|---|---|

| Hard Anodized Film | Static immersion in 3.5% NaCl, SEM, Electrochemical analysis | Superior corrosion resistance compared to powder coatings and ordinary anodized films. |

| Ordinary Anodized Heat Seal | Static immersion, SEM | Improved corrosion resistance over powder coatings but less than hard anodized films. |

| Powder Coatings (Sand & Flat) | Static immersion, SEM | Lower corrosion resistance compared to anodized films. |

Researchers have found that hard anodizing, in particular, gives shower enclosure aluminum profiles a long-lasting shield against moisture and chemicals.

Powder Coating and Other Finishes

Powder coating offers another layer of protection and style. It covers the aluminum with a thick, even coat that resists scratches and impacts. Key benefits include:

- Excellent corrosion resistance and durability.

- Wide range of color options for custom designs.

- Environmentally friendly process with low emissions.

- Proven longevity, with powder-coated aluminum lasting through years of simulated weathering.

Powder coating also makes shower enclosure aluminum look modern and fresh, while keeping maintenance simple.

Simple Maintenance Tips

Proper care keeps aluminum profiles looking new. Experts recommend:

- Spray a gentle cleaner from 6 to 8 inches away and wipe with a dry cloth.

- Avoid abrasive brushes or sponges to prevent scratches.

- Dry the enclosure after each use to stop soap and lime buildup.

- Leave shower doors slightly open for better air flow and less mildew.

Regular, gentle cleaning helps maintain both the beauty and strength of shower enclosure aluminum.

Shower enclosure aluminum profiles deliver lasting performance in wet environments.

- They offer strength, modern style, and customizable finishes for any project.

- Frameless designs reduce mold risk and simplify cleaning, keeping the enclosure attractive.

Aluminum’s corrosion resistance and advanced coatings ensure long-term reliability with minimal care.

FAQ

How do aluminum profiles stay rust-free in wet bathrooms?

Aluminum forms a protective oxide layer. This layer blocks water and air, so the metal does not rust like steel. Anodizing and powder coating add extra protection.

Can users customize the color and finish of shower enclosure aluminum profiles?

Yes. Manufacturers offer finishes like brushed gold, chrome, and matte black. Users can select from the RAL color chart to match any bathroom style.

What simple steps help maintain aluminum profiles?

- Wipe with a soft cloth after each use.

- Use mild cleaners.

- Keep doors open for airflow.

- Avoid abrasive tools to prevent scratches.