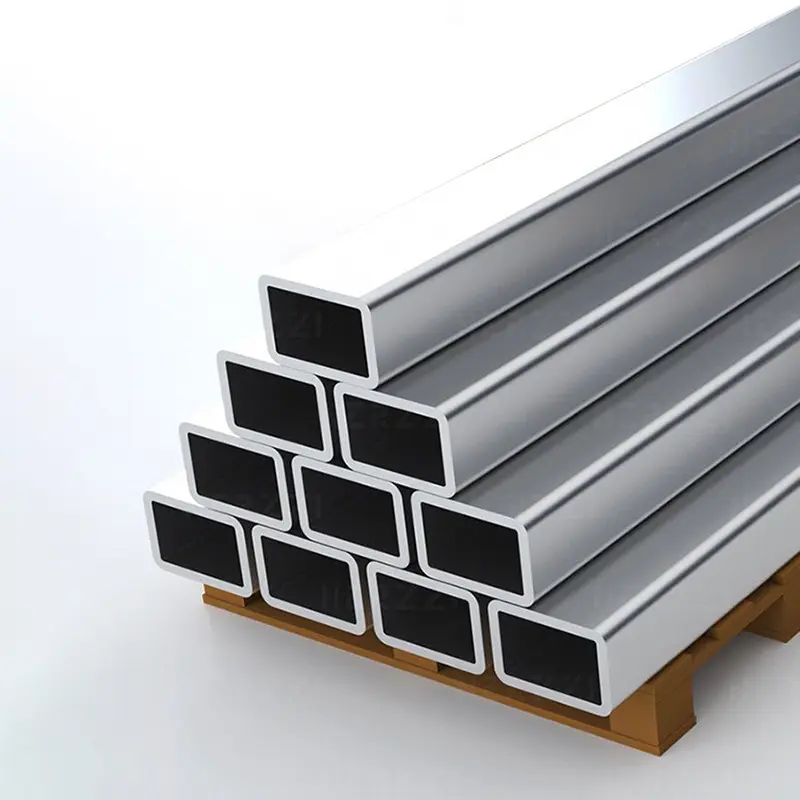

Shower Enclosure Aluminum Profiles Precision Engineered Corrosion Resistance OEM Factory

Product Description

A shower Room Aluminum Tube is a high-performance hardware component engineered to seamlessly integrate tempered glass panels with structural frameworks.

Installation Ready

Pre-drilled mounting holes (laser-marked centerlines)

Integrated cable channels for LED lighting

Sustainability

♻ 100% recyclable material

📉 30% lighter than steel alternatives

Available with BIM objects for architectural integration.

Choose Us

With the whole process of moulding, die-casting, machining, polishing, plating/powder coating/painting, inspection, assembly and shipment, we can strictly control every step of the production to ensure quality and improve product qualification rate.

Actually we provide OEM/ODM services for many famous international brands in Europe and America. For example, TOTO, Dornbracht, Roca, KLUDI.

We strictly control the thickness of plating layer of copper, nickel and chrome, usually our plating thickness is: Cu ≥ 15um, Ni ≥ 10um, Cr ≥ 0.15um, and can pass neutral 240 hours or acidic 48 hours salt spray test. We also customize your products for salt spray testing in excess of neutral 480 hours. And we promise never to use the return material directly for die-casting production.

Sincerely welcome friends from all walks of life to call us and visit our factory!